Few materials have such a wide-reaching impact as carbon black in the present industrial world. Found in everything from tires and plastics to inks and electronics, this fine black powder plays a crucial role in reinforcing, coloring, and protecting the materials that define modern manufacturing.

Though it may appear simple, carbon black is far from ordinary, it’s a high-performance additive that drives durability, conductivity, and sustainability across countless industries. Let’s explore how largest carbon black manufacturers with this remarkable material shapes the products we rely on every day.

Understanding Carbon Black: The Material Behind the Magic

Carbon black is a form of nearly pure elemental carbon produced through the partial combustion or thermal decomposition of hydrocarbons. Its microscopic particles have a large surface area and unique structure that make it ideal for reinforcement and pigmentation.

Unlike soot, carbon black is manufactured in controlled environments to achieve precise particle size, surface chemistry, and structure. These characteristics determine how it performs in different applications, whether it’s giving tires their strength, ink its deep color, or plastics their UV resistance.

The carbon black industries play a vital role in supplying a range of products to automotive, electronics, construction, and consumer goods sectors, ensuring that each formulation is optimized for durability, conductivity, and performance.

1. Reinforcing Rubber: The Backbone of Tire Manufacturing

When it comes to tires, carbon black is indispensable. Roughly 70% of global carbon black production goes into the tire industry, where it reinforces rubber compounds. Without it, tires would wear out faster, lack grip, and fail to withstand harsh conditions.

The tiny carbon particles bond with rubber molecules to improve tensile strength, abrasion resistance, and heat dissipation. This reinforcement not only extends tire life but also enhances fuel efficiency by reducing rolling resistance.

Beyond cars, carbon black is essential in rubber components like seals, gaskets, conveyor belts, and hoses, products that must endure continuous mechanical stress and exposure to friction.

2. Bringing Color and Clarity to Inks and Coatings

The printing and coating industries rely heavily on carbon black for its rich pigmentation and exceptional dispersibility. In inks, it delivers deep, uniform black tones that resist fading over time. Whether in newspapers, packaging, or high-end publications, its optical properties ensure sharp text and vivid contrast.

In coatings, carbon black serves not just as a colorant but also as a UV stabilizer, protecting surfaces from sun damage and extending product lifespan. Its light-absorbing capability makes it invaluable for automotive paints, industrial finishes, and even electronic housings.

For manufacturers aiming for both beauty and performance, carbon black remains the pigment of choice.

3. Enhancing Plastics and Polymers

Carbon black also plays a transformative role in the plastics sector. By integrating it into polymer compounds, manufacturers can improve strength, electrical conductivity, and UV resistance.

This is especially valuable in outdoor applications—pipes, films, and cables, for instance, where exposure to sunlight can cause degradation. The addition of carbon black ensures these materials maintain their integrity for years.

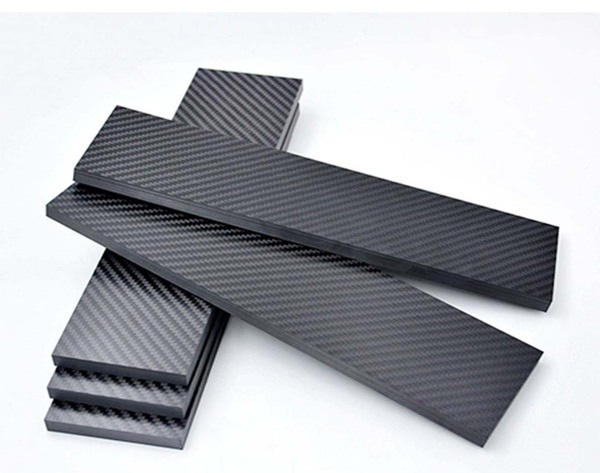

Additionally, advancements in carbon fiber plastic sheet price and composite materials have highlighted the role of carbon black in enhancing conductivity and rigidity in lightweight structures. It helps bridge the gap between traditional plastics and high-performance composites, opening up new possibilities in automotive and aerospace design.

4. Conductive and Antistatic Applications

In modern electronics and industrial equipment, carbon black’s electrical properties are as vital as its color and reinforcement abilities. When formulated into plastics or coatings, it can make materials conductive or antistatic, preventing the build-up of electrical charge that could damage sensitive components.

This is particularly important in packaging for electronic devices, data cables, and automotive sensors. Conductive carbon black ensures product reliability by maintaining safe discharge paths and reducing electromagnetic interference.

5. Sustainability and the Future of Carbon Black

As industries move toward sustainability, carbon black production is evolving. Traditional methods rely on fossil fuel feedstocks, but the largest carbon black manufacturers are now investing in cleaner processes and renewable resources.

Technological innovations such as circular carbon recovery, where end-of-life tires and plastics are converted back into usable carbon black, are gaining traction. These eco-conscious practices not only reduce waste but also cut emissions and resource consumption.

Moreover, energy-efficient furnaces and optimized reactor designs allow manufacturers to produce high-quality carbon black while minimizing their environmental footprint. The shift toward sustainable carbon black aligns perfectly with global goals for greener manufacturing.

6. The Role of Advanced Technology in Carbon Black Production

The manufacturing of carbon black is a precise process that combines chemistry, engineering, and innovation. Modern production facilities use continuous-feed reactors to control temperature, pressure, and combustion rates.

Through advanced process monitoring, manufacturers achieve consistent particle morphology and purity. The result? A versatile additive that meets exacting standards for industries ranging from automotive to electronics.

Automation and digitalization have also revolutionized the industry, allowing for predictive maintenance, reduced waste, and optimized energy consumption. In an era where precision and performance define success, technology is ensuring that carbon black remains a critical industrial material.

7. Why Carbon Black Remains Indispensable in Modern Manufacturing

Carbon black is more than just a black pigment, it’s a material that adds measurable value across every stage of the supply chain. Its ability to reinforce, protect, and enhance performance makes it essential in creating reliable, long-lasting, and sustainable products.

From the roads we drive on to the electronics we use and the packaging that surrounds our products, carbon black is quietly shaping modern life. Its applications are vast, and its potential continues to grow as innovation drives new formulations and eco-friendly alternatives.

Conclusion: The Black That Builds the Future

Carbon black’s versatility, performance, and evolving sustainability make it one of the most impactful materials in today’s industrial landscape. As technology advances, it continues to redefine how we design, produce, and protect the products around us.

Birla Carbon is among the world’s foremost pioneers in this field. They are the world’s leading sustainable manufacturer and supplier of carbon black additives, offering consistent quality across the globe. Their expert team delivers both established formulations and custom-engineered solutions for superior performance in tires, specialty blacks, and mechanical rubber goods—making them the right partner for any high-performance application.